|

|

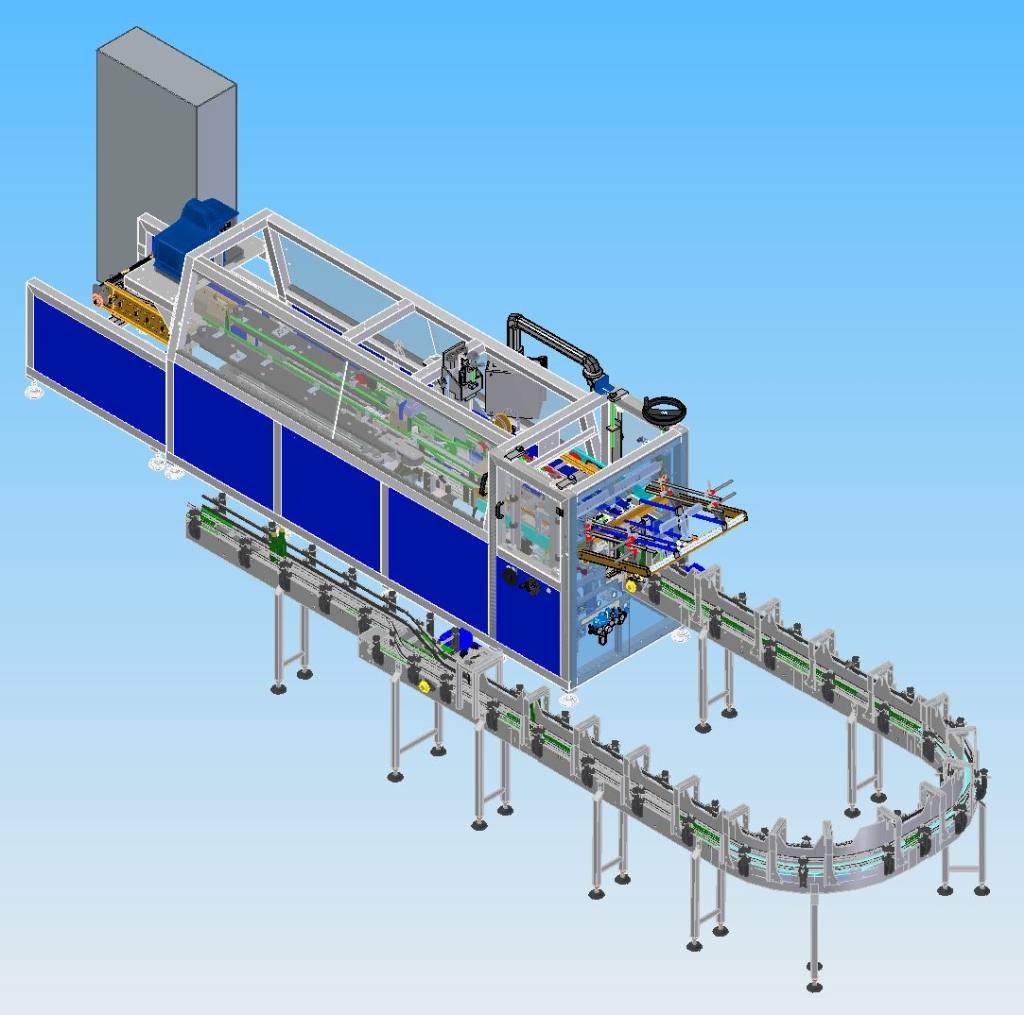

More views

Product Description

Which packing schemes can be realized:

| Formation possibilities | : 2 x 2 as well as 2 x 3 as well as 1 x to 1 x 3 |

| Bottle types | : e.g. 0, 33 l LN - bottle, 0,5 L NRW - bottle |

| Other bottles on request | |

| Closure | : hot glue closure bottom area |

Capacity of the machine

- Max. 100 packs/min with formation 2 x 3

- Changeover time approx. 10 minutes of the packing unit

- Blank magazine : max. 1.500

Overview of the individual stations

- Stainless steel frame

- Double-sided single-cycle starwheels in the infeed area (starwheels can be changed for different diameters by means of simple rotary latches)

- Orbiter for bottle separation

- Blank infeed with magazine and blank suction system

- Blank closure with hold-down device, pressure belt, folder, tension chain, folding rails

- Bottom closure with hot melt / glue application system

- All stations can be adjusted by spindles

Control and drive technology

- Control Siemens S 7 - 1500

- Servo drives from Siemens as main drive

- Siemens PLC with 12 inch HMI Touch

- Control cabinet integrated

- Protective enclosure with door safety switch and magnetic guard locking

- Servo drives for formation

Advantages

- Easy changeover between bottle types and formation formats

- Closing section with clamping finger for optimum pack strength

- Pressure belt with folder (synchronous servo motor)

- Monitoring of pack completeness

- High degree of accessibility

- Short set-up times and a high degree of flexibility

- Good user friendliness due to visualized touch panel

Technical data

| Category: | Multipack machine |

| Automatic: | Fully automatic system |

| Fabrication: | Multipacker |

| Typ: | MP 100 |

| Year of construction: | new |

| Capacity per hour from: | |

| Capacity per hour to: | 36.000 bottles |

| Packaging: | 100 Sixpacks per min |

| Number of lanes: |