Filling of cocktails in reusable plastic cups

The aim of this project was to fill a cocktail cup and insert chunky fruit. After the filling process, the reusable cups are closed with an aluminum plate and fed into the packaging. Our highly flexible adaptation to customer requirements opens up scope for special machines.

Functional process

|

First, the cups are unstacked from the cup magazine and further cycled on the infeed conveyor. Various products, such as fruit or spices, can be added to the cup manually. The infeed conveyor then transfers the cups in cycles to the filling machine. In the line, the cups are now transferred to the first placeholder, the ice station. In this station, a customer-side mechanical insertion of several ice cubes is provided. Once the cups have been filled with ice, the cup is released and the filling station is approached, where a fruit juice containing alcohol is filled. |

The aluminum lid is then placed in the lid station and sealed airtight with the cup in the downstream sealing station. Finally, the finished cup is transferred to the outfeed conveyor and can be further processed at a collection table or elsewhere. The demand for sustainable products is constantly increasing. The cups can be easily cleaned after use. Even after multiple sealing, the sealing is still very good. |

|

|

|

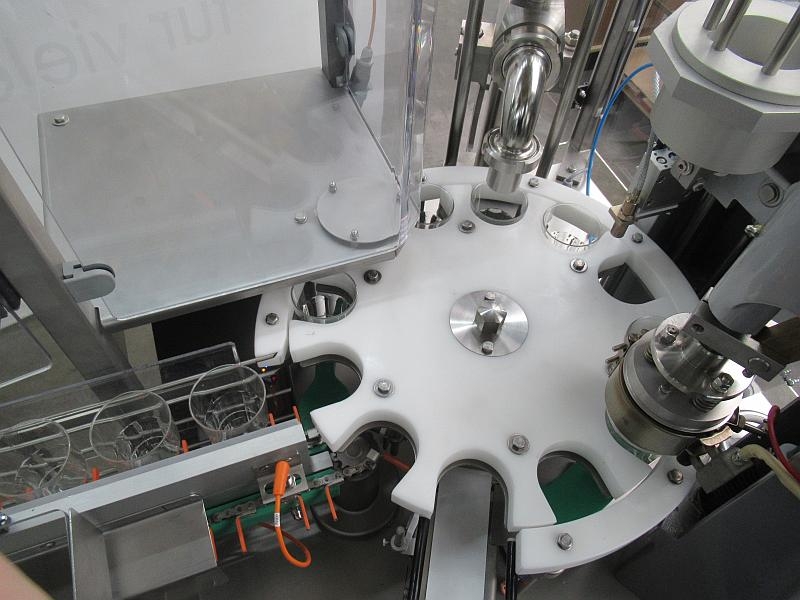

Rotary table and stations |

Complete machine with cup infeed and outfeed |

MACHINE DETAILS

- Flexible filling line for cocktails

- max. 2000 cups / hour

- Cup: Ø 70

- Flexible cup magazine

- Automatic clocking

+49 (0) 1590/ 418 89 60

+49 (0) 1590/ 418 89 60